Material: Iron steel wire or stainless steel wire

Certificate: SGS, BV, ISO9001, ISO14001, ISO45001

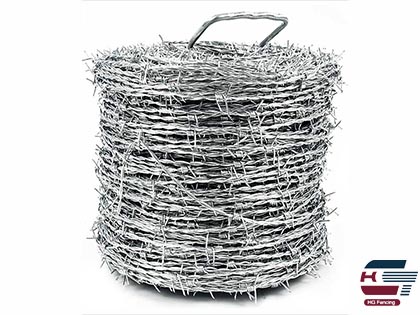

Brand: HG Fencing

Manufacturer: HUA GUANG

Origin: China

Barbed wire also named bobbed wire, is made from high quality steel or stainless steel wire with special spikes, which can be formed into barbed wire fences or installed on top of fences to make it difficult for people or animals to climb or cross. It can be used in a wide range of applications, such as on farms for raising livestock or in high security areas such as highways, railways, military bases, prisons and airports.

● The barbed wire has sharp barbs to effectively deter intruders.

● Barbed wire has very good corrosion resistance and can be used for more than fifteen years.

● PVC covered barbed wire is available in a variety of colours for better application in the environment in which it is used.

● Barbed wire is easy and quick to install, saving labour and costs.

● The application is very wide, can be used in farms, home protection, military bases, etc.

● Material: galvanised Steel wire, PVC/PE coated steel wire, stainless steel wire, zinc-aluminium alloy wire.

● Wire Diamter: 1.0mm - 4.0mm

● Strand structure: single strand barbed wire, double strands barbed wire, three strand barbed wire

● Barb structure: 2-point barbed wire, 4-point barbed wire

● Twist style: conventional twist barbed wire, reverse twist barbed wire.

| Barbed Wire Specification | ||||

| Type | Wire Gauge (SWG) | Barb Distance (cm) | Barb Length (cm) | |

| Electric Galvanized Barbed Wire; Hot-dip zinc plating barbed wire | 10# x 12# | 7.5-15 | 1.5-3 | |

| 12# x 12# | ||||

| 12# x 14# | ||||

| 14# x 14# | ||||

| 14# x 16# | ||||

| 16# x 16# | ||||

| 16# x 18# | ||||

| PVC coated barbed wire; PE barbed wire | before coating | after coating | 7.5-15 | 1.5-3 |

| 1.0mm-3.5mm | 1.4mm-4.0mm | |||

| BWG11#-20# | BWG8#-17# | |||

| SWG11#-20# | SWG8#-17# | |||

| PVC / PE coating thickness: 0.4mm-0.6mm; different colors or length are available at customers request. | ||||

● Galvanized barbed wire

is the most common type of barbed wire and is very resistant to corrosion and can be used in humid and hot environments and has a long service life. It can be divided into hot-dip galvanised barbed wire and electro-galvanised barbed wire.

● PVC/PE coated barbed wire

with low carbon steel wire or galvanised wire inside for excellent corrosion resistance. It is also available in a wide range of colours to suit different environments.

● Stainless steel barbed wire

which has the highest corrosion resistance, includes 304, 316, 316L etc. It is rust-free for life and has a bright and beautiful surface.

● Zinc and aluminium coated barbed wire

Zinc-aluminium barbed wire. The surface coating consists of zinc and aluminium elements. There are two types: 5% aluminium-zinc alloy wire barbed wire (Galvanised coating), and 10% aluminium-zinc alloy wire barbed wire. Compared to conventional galvanised barbed wire, it has greater corrosion resistance.

● Singe strand barbed wire

with its simple construction consisting of a main wire with barbs, is cheap, light and easy to install for general scenarios. However, single strand barbed wire is not strong, can be easily damaged and is not as secure as double strand barbed wire.

● Double strand barbed wire

as the name means, consists of two main wires and barbs, the two main wires being twisted around each other. It is stronger and has a higher tensile strength. It is not easily damaged and is the most widely used type of barbed wire, mainly in airports, prisons, military bases and other security locations.

● Three strand barbed wire

consisting of three main wires and barbs, with the three main wires tightly entwined and the barbs fixed to the main wires, is the strongest and most resistant of the three types of barbed wire. It is suitable for use in high security applications such as heavily guarded prisons and anti-intrusion fencing in warfare.

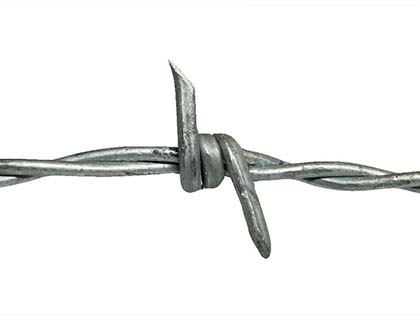

● 2-point barbed wire

as the name suggests, has 1 barbed wire wrapped around each section, above the main wire, which has two barbs. 2 point barbed wire is simple in construction and inexpensive. It is suitable for general use, such as raising livestock in pastures.

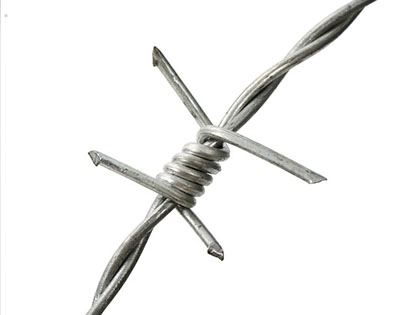

● 4-point barbed wire

4-point barbed wire, which is in each section, has 2 barbed wires wrapped around the main wire, each with two barbs.

The 4-point barbed wire is the most widely used, has a higher degree of protection and is suitable for most scenarios.

● Conventional twist barbed wire

The barbs are first wound onto the main wire (i.e. a single wire) and then twisted together with another wire to form a double barbed wire. This barbed wire is cheap and simple, with the barbs between the two wires, and is suitable for common scenarios.

●Reverse twist barbed wire

The barbed wire is twisted in the opposite direction from the point where the barbed wire is wrapped around the main wire. It is not twisted in one direction. Compared to ordinary twisted barbed wire, this type of barbed wire has a higher tensile strength and is able to withstand larger impacts, making it suitable for applications with higher security requirements.

Huaguang uses high quality iron wire, which is woven into barbed wire by fully automatic barbed wire weaving machines. With over 30 weaving machines, we are able to produce barbed wire in various sizes and can accept custom-made products.

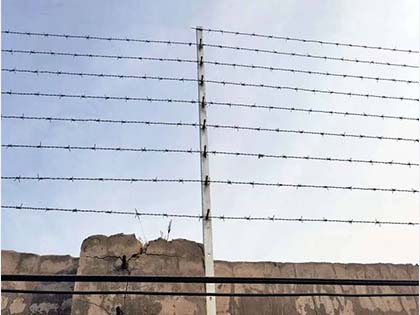

Barbed wire is very widely used as a security material.

● Barbed wire can be used on its own to form barbed wire fences and can be applied on farms to prevent livestock from escaping and to keep other animals out. It can be used on both sides of roads or railways to prevent people from entering, or on battlefields, or military bases to prevent enemy incursions.

● Barbed wire can also be installed on top of fences or walls to increase security and can be used in airports, prisons, factories or around homes.

Welcome To Visit Our Factory!